Cost for Sales

Understanding your Cost Base and being 'Open Book'

The Challenge

The modern market place is asking for more and more transparency, in some cases being fully open book. Refusing to comply can result in being excluded from the bidding process, but being transparent shares a level of detail that some companies are not comfortable with. Part of the unease can be attributed to trust, but a lot of it comes from low confidence in the base data, and fear that the margin may be completely eroded during the negotiation. Using our tools and techniques it is possible to overcome this unease. It is also possible to look at areas of risk mitigation and learner where applicable.

The Solution

The bid process for any project is very personal to the supplier bidding. The manufacturing process may utilise capacity on existing equipment, or may be a dedicated cell built specifically for the project. Either way it is the skill of the Manufacturing Engineering Team that defines the technical basis of the bid, and the commercial team generally wrap the numbers around this. Using Cost Engineering tools to bring these two stages closer together can give a far more joined up solution, and allows the key cost drivers to be identified and optimised :-

1) Material Selection

The material a product is made of often drives a large portion of the cost and generally determines a lot of the cost drivers relating to the final manufacturing process. Consideration should also be made to the supply region and the availability of the material specified within that region. Whilst there is often equivalence between common materials, some of the more exotic types may be difficult to source in far flung regions. Many customers will happily provide an equivalent material specification that can be sourced in region without incurring duties and shipping making the bid unattractive.

Some larger Tier 1's and OEM's have an ability to pass through negotiated material prices to the supply chain from their own global deal. It is important to ask for this as not doing so can make a bid look unattractive.

2) Condition of Supply

The condition of supply assumptions (i.e. bar, casting, forging etc.) will also drive the manufacturing cost. In an ever more global market place some of these norms are now being challenged. Parts that were historically cast and machined in the west may now be sourced cheaper in low cost regions directly from bar, especially if the volumes are low. Cost analysis of these scenarios can identify the business case for each, and even determine where during a ramp-up it is economic to change if required. This can also apply to the production ramp down phase and aftermarket demand at the end of the product lifecycle. Considering this in the bid stage can make the lifecycle cost look more attractive and make the overall bid more competitive.

If castings or forgings are required, and the part is being sourced in a low cost region, it makes sense to source the casting or forging in the same region, and to manage this. This will have an impact on the overall component price and all these scenarios can be analysed with our cost models to ensure good value is delivered. Our tools can help the sales team validate the bids and train them how to recognise opportunity in Raw Material and Condition of Supply.

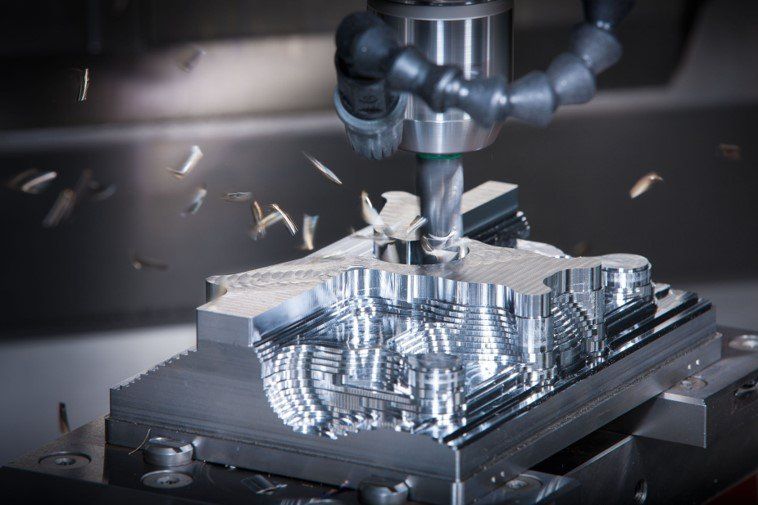

3) Manufacturing Process

The manufacturing process is often the biggest differentiator between supplier bids. Whether it's fitting the part into existing capacity on a shop floor or new dedicated cell, the expertise of the supplier will have a big impact on the process design. Some suppliers will have more in-house capability than others, and as such may choose to sub-contract some of the operations. This needs to be managed and presented carefully by the sales team, as poor sourcing and multiple layers of overhead and profit can damage a bid. Detailed Cost Models can help understand this, and we can provide this capability as a sub-contract service, or train personnel within a client to do this for themselves.

4) Machine Selection

The equipment used to produce the finished part inevitably has an impact on the cost. This is driven by the volume of parts to be produced, and also the complexity of the design (as mentioned above). Over investment in machinery can be surprisingly common, resulting in inflated manufacturing cost rates. Putting a product on the wrong machine (too big, too complex etc.) can have the same effect. Changes in product mix on shared equipment can change the economies of established processes, making an a previously robust make v. buy decision more uncertain. Again, robust cost modelling can identify and avoid a lot of these issues, helping to identify anomalies in the bid that may need to be addressed before presenting to the customer.

5) Region Selection

In the ever more global environment we live in there can be a lot of pressure on manufacturers to off-shore their production to perceived low cost regions. Experience shows us that this is not always the magic bullet originally thought, and depending on the volume of products and the complexity of the design can deliver very poor benefits. Even when based in a higher cost region it is possible to prepare a successful bid, applying good Cost understanding and minimising waste. Reviewing the entire supply chain assumptions as part of the cost model can help clarify this issue, and this 'total cost of acquisition' concept can be invaluable.

6) Transparency

Completing the customers cost capture document (QAF, CCW, RFQ etc.) can seem a very one sided step in the bid process. Having been through the process many times with many suppliers we see there are more benefits than downsides if the manufacturer understands their cost base and has a robust process. The biggest area of disagreement often stems from attitude to risk, and our approach looks to bring this to the forefront and manage it jointly. We can train sales teams on how to complete the documentation in the optimum way, and ensure the company is not exposed whilst still presenting an attractive bid. Using our many years of experience we can point out the most common errors, and ensure these mistakes are no repeated!