Cost for Design

Understanding the "Art of the Possible" for "As little as Possible".

The Challenge

Every successful product is the fruit of hard work and this applies to every field of business. Even the most unique products must still represent value for money or they will not sell. Understanding the price the market will pay and how this compares with the cost to manufacture allows the business to understand profitability of the product from job #1. Analysing the cost through the ramp up stage allows cash flow to to be managed, and can help drive investment phasing. Our cost modelling techniques help to support all this, even before the design starts, by analysing similar parts and products and working from CAD.

The Solution

Managing the Design to Cost process can start before the design cycle actually starts. If the market analysis work is complete then the target unit cost may have already been calculated, giving the designer something to aim for. Even if this data is not available, the same steps can be followed :-

1) Study existing or similar parts

Identifying the cost drivers for existing parts if the design is an evolution can provide a wealth of information, such as material choice, supply chain constraints, and historical areas of manufacturing complexity. Not repeating mistakes of the past is a good way to drive positive change. If the supply chain is established then the current manufacturer can often support this too.

2) Material Selection and Condition of Supply

The material a product is made of often drives a large portion of the cost and generally determines a lot of the cost drivers relating the the final manufacturing process. Whilst the function of the part will inevitably also have a part to play in the material selection, the condition of supply assumptions (i.e. bar, casting, forging etc.) will also drive the manufacturing cost. In an ever more global market place some of these norms are now being challenged. Parts that were historically cast and machined in the west may now be sourced cheaper in low cost regions directly from bar, especially if the volumes are low. Cost analysis of these scenarios can identify the business case for each, and even determine where during a ramp-up it is economic to change if required. This can also apply to the production ramp down phase and aftermarket demand at the end of the product lifecycle.

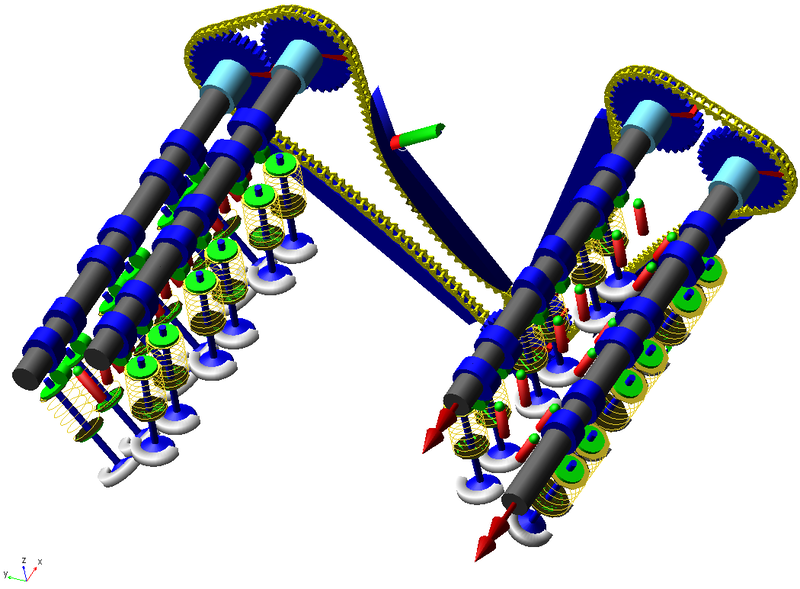

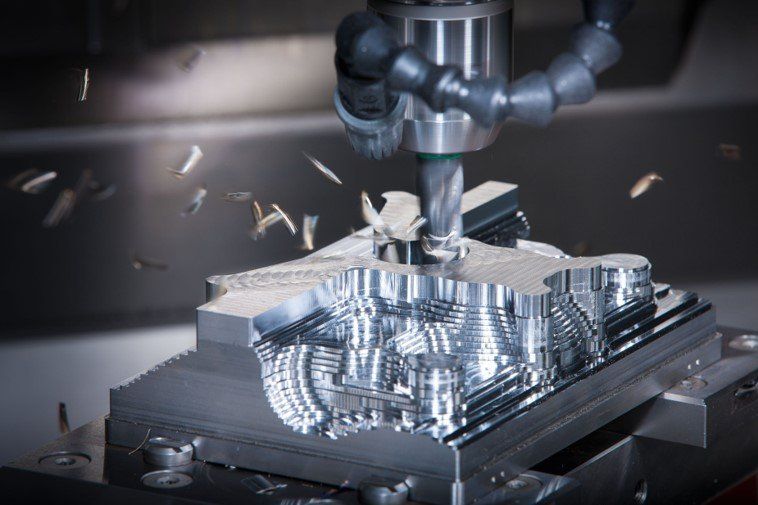

3) Manufacturing Process

Throughout the design process it is possible to produce a cost model for the part, even when a lot of the final design is not clear. As the design develops the model is updated, and as long as the assumptions are understood then valuable data can be obtained which feeds back into the design. Identifying tight tolerances, rigidity issues, or access issues for welding and machining, are amongst the many valuable lessons. Keeping features in the standard geometric plane can minimise machine set-ups and also simplify any inspection requirements. This data driven feedback is invaluable to the design process, where the designer often has little understanding of how their final part will be produced. Keep it simple is easy to say, but our data helps quantify this!

4) Machine Selection

The equipment used to produce the finished part innevitably has an impact on the cost. This is driven by the volume of parts to be produced, and also the complexity of the design (as mentioned above). Over investment in machinery can be surprisingly common, resulting in inflated manufacturing cost rates. Also, changes in product mix on shared equipment can change the economies of established processes, making an a previously robust make v. buy decision more uncertain. Again, robust cost modelling can identify and avoid a lot of these issues, making a positive impact on the business case.

5) Region Selection

In the ever more global environment we live in there can be a lot of pressure on manufacturures to off-shore their production to perceived low cost regions. Experience shows us that this is not always the magic bullet originally thought, and depending on the volume of products and the complexity of the design can deliver very poor benefits. Reviewing the entire supply chain assumptions as part of the cost model can help clarify this issue. As mentioned above there can be instances where region selection and manufacturing process can feed back into the core design, so understanding this 'total cost of acquisition' concept can be invaluable.