Cost for Purchasing

Understanding 'What Drives the Price?' of the things we Buy

The Challenge

The role of the buyer in any organisation is becoming ever more complex. More technically challenging products, longer more global supply chains, and often more accounts to manage, all combine to make the buyer's role more and more difficult. Expecting the buyer to have all the commercial knowledge required to manage the contracts, as well as enough technical knowledge to challenge expert sales teams, is becoming unrealistic. Our Cost Engineering tools provide the support required to streamline the whole process, and come the aid of the busy Buyer.

The Solution

The Design of the Manufacturing Process can start during the design cycle if time permits, as discussed in the Cost for Design section. If the market analysis work is complete then the target unit cost may have already been calculated, giving the Manufacturing Engineers something to aim for. Even if this data is not available the same steps can be followed, and the process can also be applied to existing parts if required :-

1) Material Selection

The material a product is made of often drives a large portion of the cost and generally determines a lot of the cost drivers relating to the final manufacturing process. Consideration should also be made to the supply region and the availability of the material specified within that region. Whilst there is often equivalence between common materials, some of the more exotic types may be difficult to source in far flung regions. Many suppliers will take a drawing literally and try to source the specified material from outside their region, possibly incurring duties and shipping that a domestic supplier will not get. This can skew a quote and a good supplier can be deselected just for the sake of smart material selection.

Some larger Tier 1's and OEM's have an ability to pass through negotiated material prices to the supply chain from their own global deal. This benefit sometimes get's ignored and again can skew a bid.

2) Condition of Supply

The condition of supply assumptions (i.e. bar, casting, forging etc.) will also drive the manufacturing cost. In an ever more global market place some of these norms are now being challenged. Parts that were historically cast and machined in the west may now be sourced cheaper in low cost regions directly from bar, especially if the volumes are low. Cost analysis of these scenarios can identify the business case for each, and even determine where during a ramp-up it is economic to change if required. This can also apply to the production ramp down phase and aftermarket demand at the end of the product lifecycle.

If castings or forgings are required, and the part is being sourced in a low cost region, it makes sense to source the casting or forging in the same region, or ideally get the machinist to do this. This will have an impact on the overall component price and all these scenarios can be analysed with our cost models to ensure good value is delivered. We can help the buyer validate the bids and train them how to recognise opportunity in Raw Material and Condition of Supply.

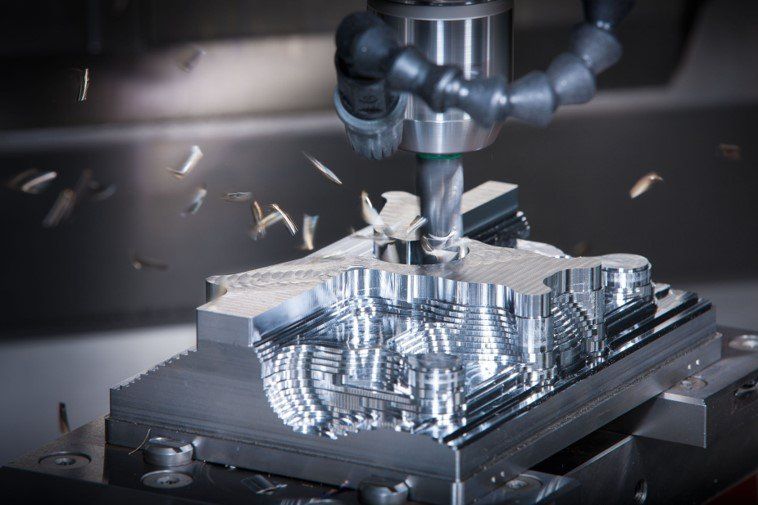

3) Manufacturing Process

The manufacturing process is often the biggest differentiator between supplier bids. Whether it's fitting the part into existing capacity on a shop floor or new dedicated cell, the expertise of the supplier will have a big impact on the process design. Some suppliers will have more in-house capability than others, and as such may choose to sub-contract some of the operations, leading to wildly differing prices. On a complex part the combinations and permutations can be mind blowing, but using standardised cost models to identify the high impact processes can greatly simplify the analysis. We can provide this capability as a sub-contract service, or train personel within a client to do this for themselves.

4) Machine Selection

The equipment used to produce the finished part inevitably has an impact on the cost. This is driven by the volume of parts to be produced, and also the complexity of the design (as mentioned above). Over investment in machinery can be surprisingly common, resulting in inflated manufacturing cost rates; or putting a prodcut on the wrong machine (too big, too complex etc.) can have the same effect. Changes in product mix on shared equipment can change the economies of established processes, making an a previously robust make v. buy decision more uncertain. Again, robust cost modelling can identify and avoid a lot of these issues, helping to deliver value for money for the buyer.

5) Region Selection

In the ever more global environment we live in there can be a lot of pressure on manufacturers to off-shore their production to perceived low cost regions. Experience shows us that this is not always the magic bullet originally thought, and depending on the volume of products and the complexity of the design can deliver very poor benefits. Reviewing the entire supply chain assumptions as part of the cost model can help clarify this issue, and this 'total cost of acquisition' concept can be invaluable.